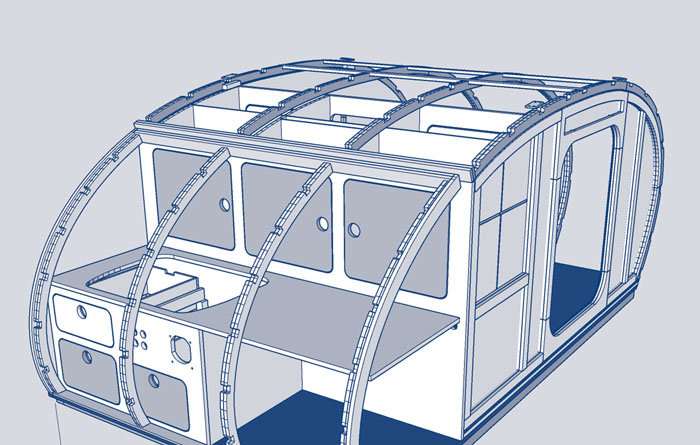

We designed and created this unique wooden birdcage for some breakout spaces at a large Fintech event in Copenhagen. Each piece was CNC cut before being assembled in the workshop before being carefully transported over to Denmark.

Creative design and CNC manufacture from a passionate and experienced team of makers.

WHO WE ARE

We are a professional and down to earth team of designers and makers based in Frome, Somerset.

We provide a CAD & CNC design and cutting service for creatives, trades, businesses and everything in between, with a wide range of complimentary skills to help you bring your ideas to life from initial concept to completed product.

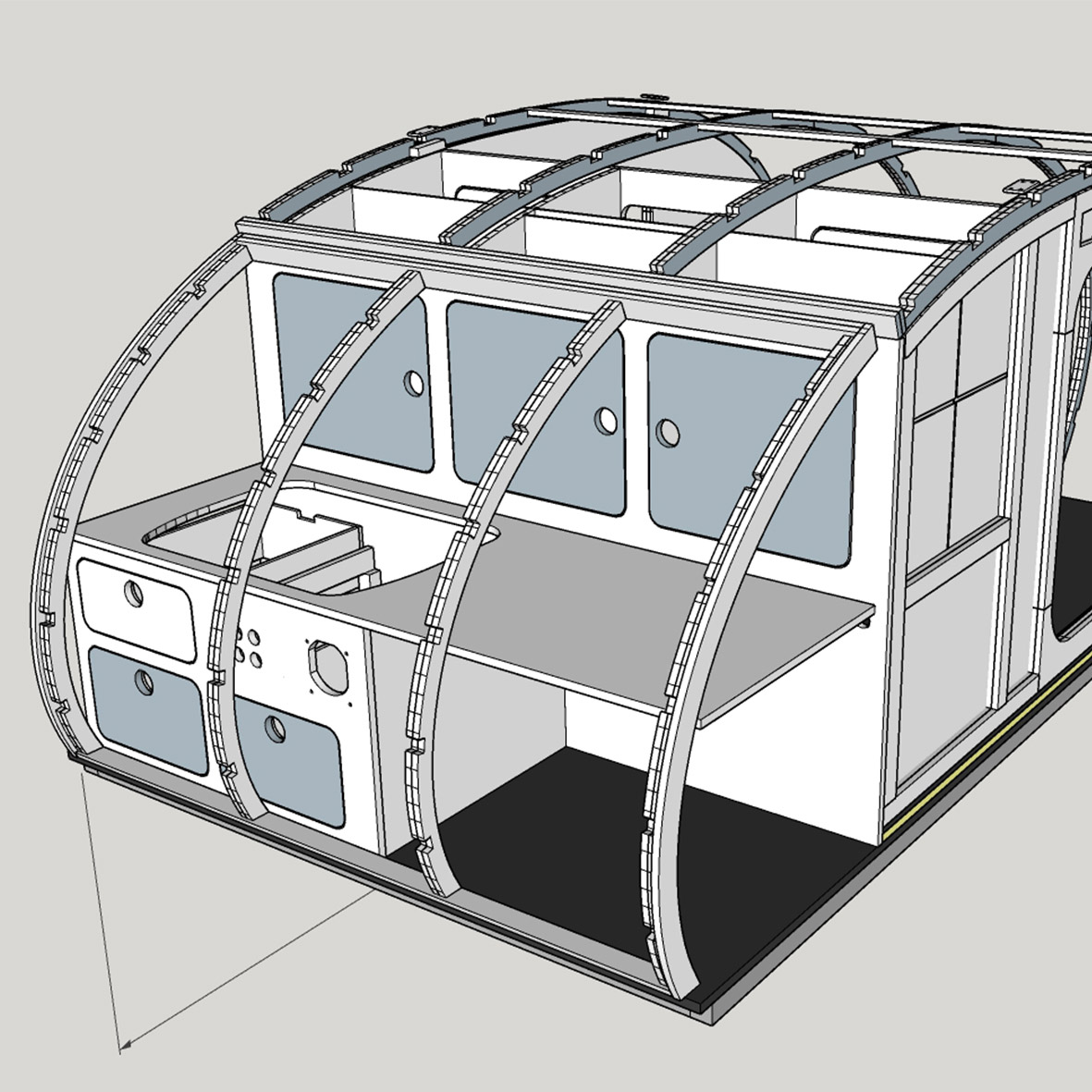

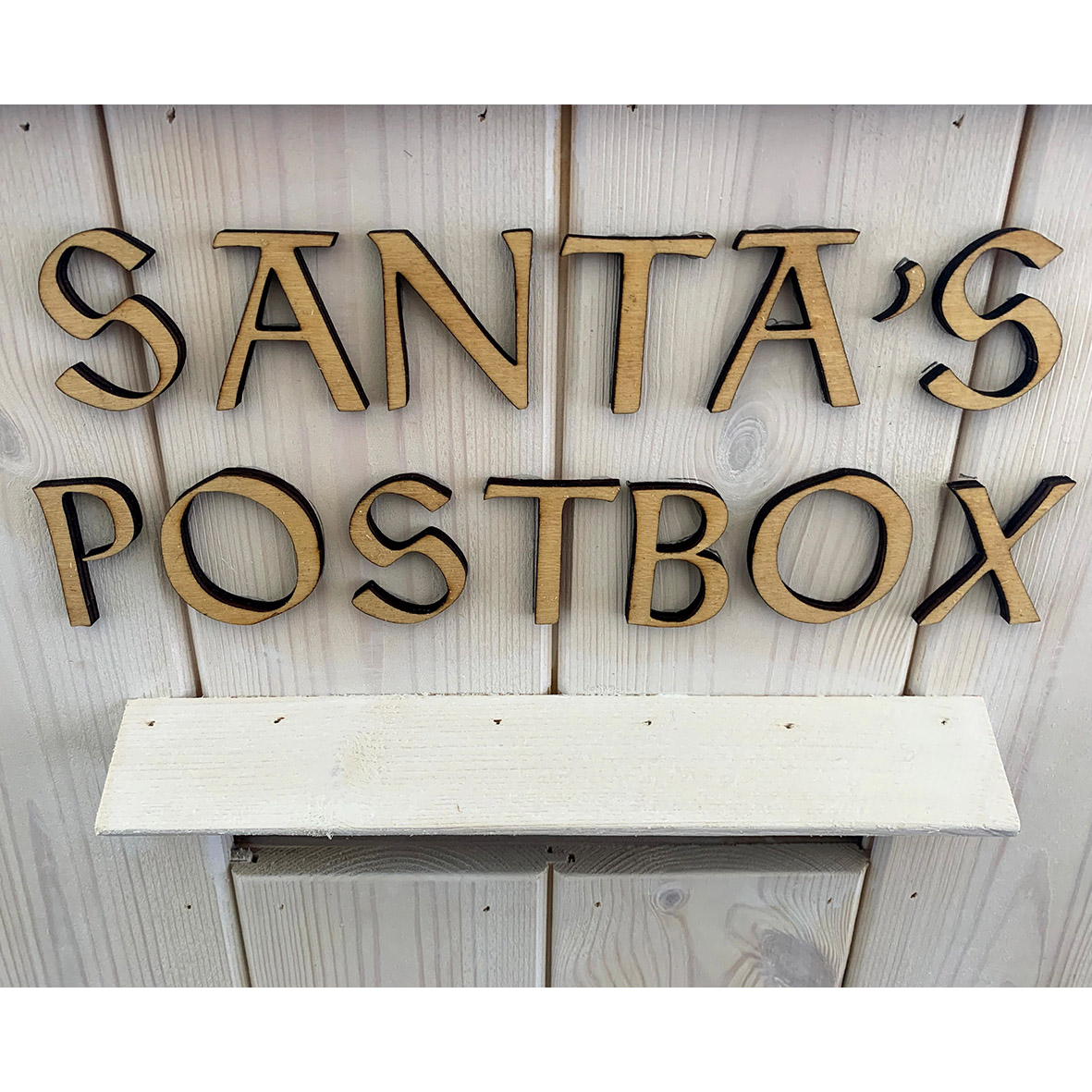

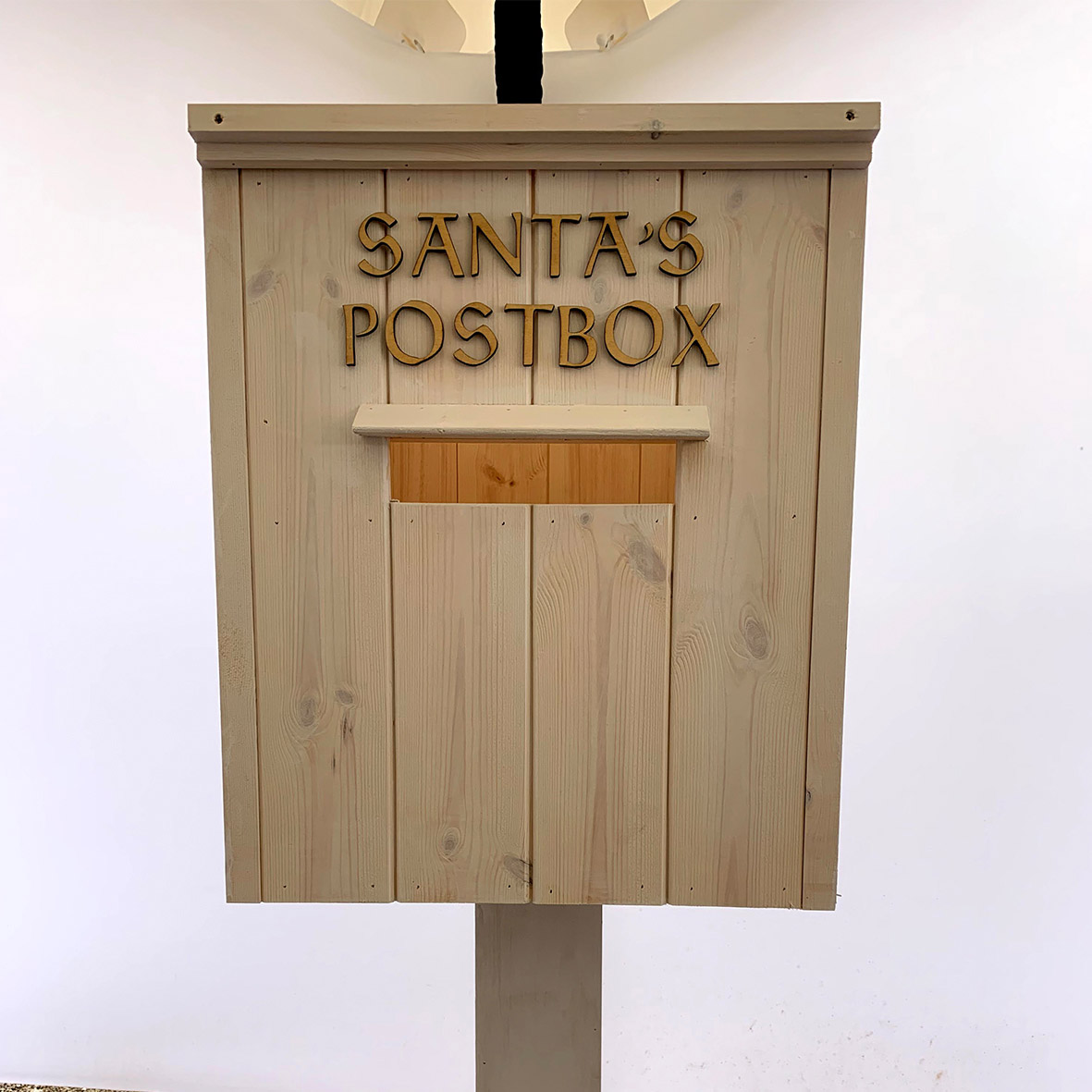

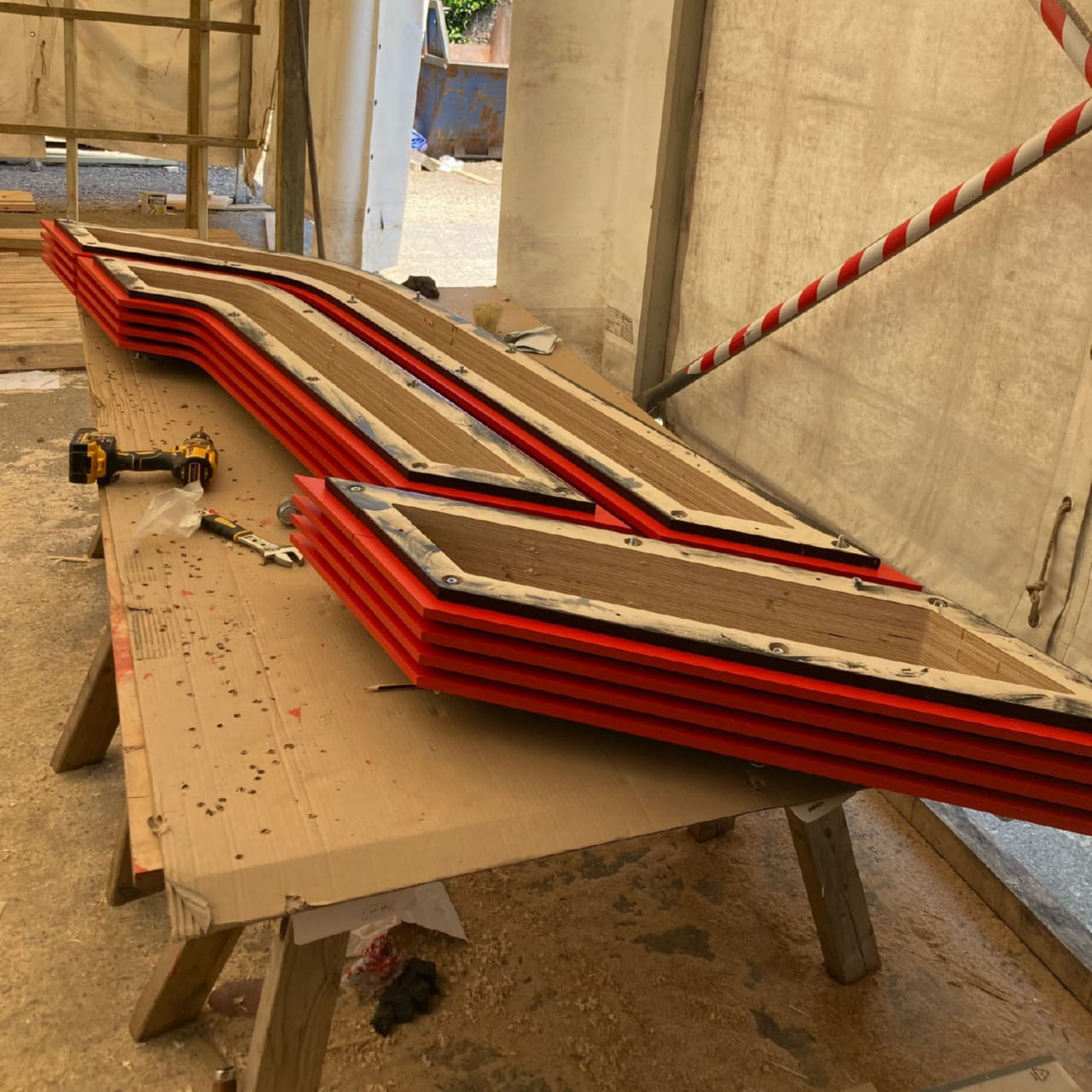

Our experience in CNC manufacturing includes design and build for events, experiences, exhibition stands, bespoke signage, interiors for business and residential, furniture design and teardrop trailer/ campervan conversion.

WHAT WE DO

CONCEPT / DESIGN / MANUFACTURE

CONCEPT

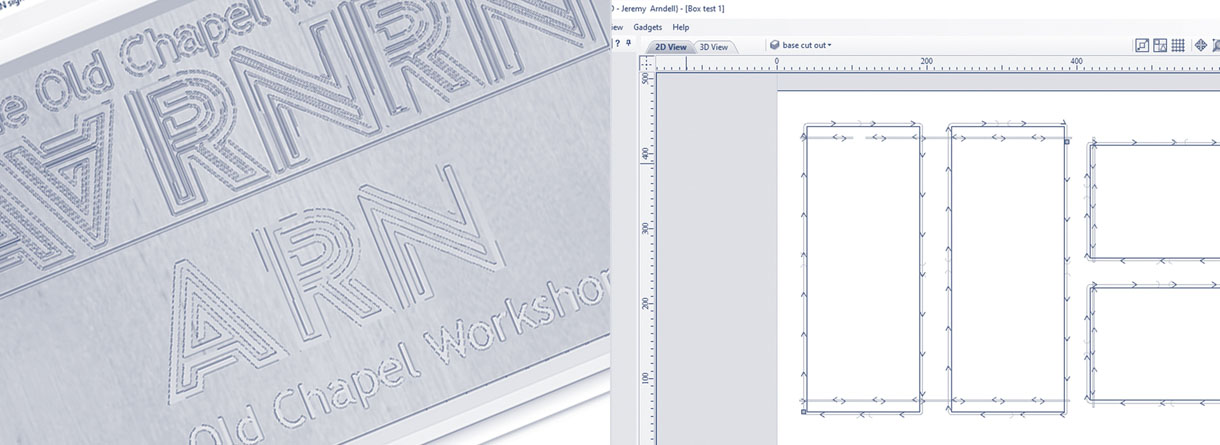

Send us your idea / moodboards / drawings / sketches and we’ll design them up into usable files before cutting them for you in the material of your choice.

DESIGN

CAD –

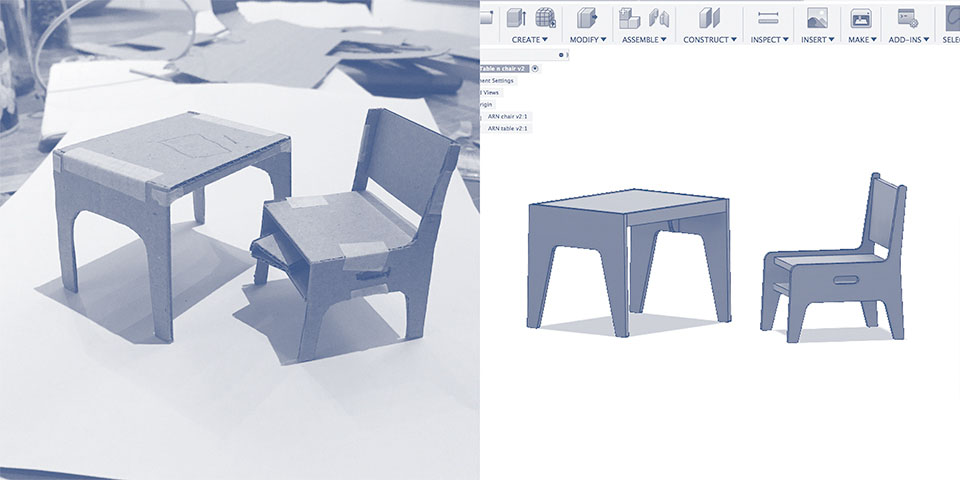

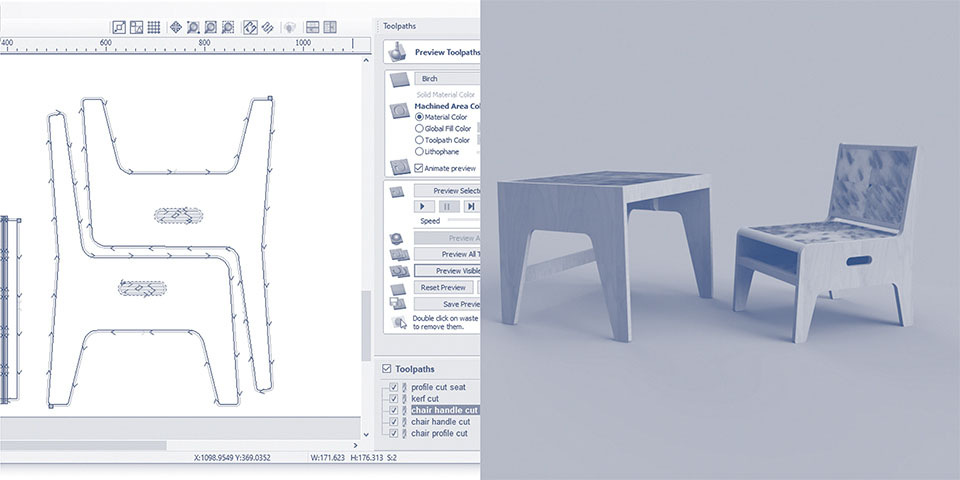

Need some extra direction? Use our Computer Aided Design expertise to turn your ideas into 3D visuals before making them ready for the machine.

MANUFACTURE

CAM –

Need more than a one-off? We can develop your designs and use specialist Computer Aided Manufacture software to create efficient manufacturing processes for your product. These processes give us the ability to cut complex shapes and to cut them exactly the same time after time. We can take your concepts and develop them into a real 3D object from wood or plastic.

MATERIALS

Our Pegasus machine can rout and cut a range of materials. From MDF, Plywoods, Valchromat, Chipboard and Solidwoods to plastics such as Acrylic, PVC, Correx, Polypropylene, Foamex and Polycarbonate, we can handle it.

If you’d like to cut a material not listed here, just drop us an email and we’ll do our best to help. We can source materials for you or cut what you provide.

WORKSHOP

Our sister company ARN Design can provide a complete design, manufacture, assembly and finishing service for your product from our well equipped workshop.

PRODUCTION MANAGEMENT

Looking for something to make your event, brand experience, pop up or exhibition stand out? Our creative production partner Positive Experience can help.

Tackling all stages of design and build, they can generate concepts, design products for CNC, assemble and finish them in our workshop and then install on multiple sites. They’ll even manage the full logistics of touring and building the assets in multiple locations, drawing on their many years’ experience of doing this around the UK and Europe.

Visit www.positiveexperience.co.uk for more information or drop us an email.

Our work

Some of our favourite projects so far.

Team

Jeremy

Director

Jeremy passed his Design Degree in 1996 and promptly went into live music and venue management. He helped run the De Montfort Hall in Leicester for half a decade during which time he helped set up three music festivals. Making the move into event production seemed like the obvious choice and he worked on numerous events over the next few years as a self employed Production and Site Manager (Larmer Tree, Summer Sundae, End of the Road, Glastonbury).

Then family life became the new priority, so a more settled approach led to taking on some property development and from that moving into carpentry. Reviving some events contacts Jeremy managed to swing a few contracts making bespoke items for events, which led to bigger projects which led to… well you get the picture. Skip on a few more years and you’ll find him in his own workshop designing and making all sorts of weird and wonderful stuff for all sorts of weird and wonderful people. Which is how he met Rik, who’s certainly wonderful…

Through this Jeremy has lots of experience in CAD so a jump to setting up a CNC business seemed like an excellent adventure as he really likes designing and making cool, interesting stuff and what better way to do it than with a great big computer controlled routing machine?

Ross

Designer & Maker

Being passionate about design and making from a young age Ross pursued a degree in Product and furniture design at De Montfort University in 2017. During this time he gained lots of experience especially while on his placement year working for a renowned bespoke joinery company. Ross received multiple design awards throughout his studies and graduated with a first class honours.

Post graduation he wanted to apply his design skills and broadening his knowledge in the sustainability sector, so accepted a role at the University of Bath. Ross would help advise on new campus builds and retrofits of old buildings to help improve their energy efficiency while reducing their carbon impacts to our environment. He explains ‘our design decisions have a direct impact on our natural environment, by being in touch with this allows me to make better decisions when designing clients projects’.

Fast forward to 2021, Ross was welcomed to the creative team at ARN, where he designs, makes and operates our in house cnc machine and laser cutter. Since being here Ross has had the pleasure of working with household named brands, local businesses and independent people, turning their ideas into a reality.

When he is not in the studio Ross enjoys spending his time: going to the gym, swimming, finding new places to travel, or on the hunt for the best pint with his mates.

Nero

Chief chewabilty consultant.

As chief chewability consultant Nero works tirelessly to oversee the workshop and its hidden stash of tennis balls. For his important work he holds the long standing record for employee of the month. He is very patient with the team when walks and fetch are not at the top of the to-do list. Nero also handles the complaints department.